Laser tracking machines are often referred to as portable coordinate measuring machines. A laser tracker is a piece of technology built with one purpose – dimensional inspection. This can be of large equipment, such as huge assemblies or individual pieces of equipment. Laser trackers are often used to check the alignment of wheels, too, during the vehicle manufacturing process.

Taking such precise measurements of large equipment or even checking wheel alignment can be a tedious undertaking. And it can be very easy for human error to slip in, leading to issues developing. Laser tracking equipment eliminates this problem, taking pinpoint measurements that are easily repeatable of machinery or wheel alignment. As a result, even the most minor misalignment can be spotted and remedied quickly.

Laser trackers can be implemented indoors and outdoors and work so that no dismantling is necessary. This makes laser trackers an excellent time-saving tool.

Typically, laser tracking equipment can be used in conjunction with computer software to provide incredibly fast and accurate feedback in real-time. That’s why such devices are favoured in manufacturing environments, such as car manufacturers for checking components like wheels.

In fact, there is a wide range of common applications for laser tracking equipment, besides just checking wheels, including:

- Machining

- Design

- Assembly

- Inspection

- Installation

- Maintenance

- Repair

- Manufacturing

They can be used to check a whole array of things, from wheels to turbines, compressors, CNC machines, pumps, etc. Such things are usually found in engineering setups and must be correctly calibrated to mitigate safety risks and downtime while maintaining operational efficiency.

Furthermore, laser tracking equipment is also ideally suited to machining (as mentioned above), providing real-time feedback on critical geometry controls. Laser tracking equipment easily surpasses all other methods for precision, regardless of the circumstances, able to comfortably handle cylindricity, circularity, parallelism, and planarity.

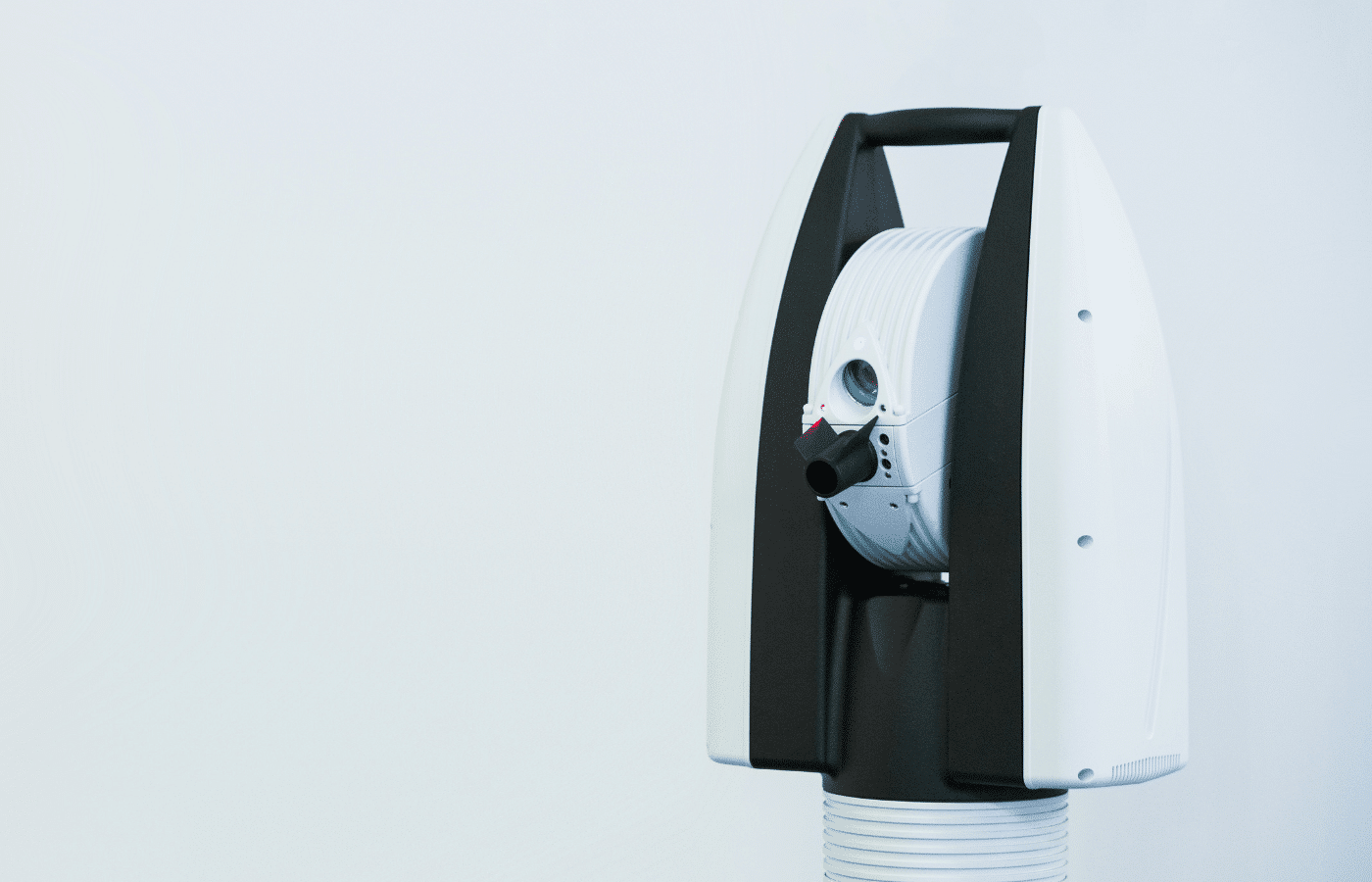

But how does laser tracking equipment work? First, they take precise large-volume measurements of parts, tooling, and assemblies. They have a large working radial volume and support accuracies up to 0.001in. They measure two angles and a distance, and they do this by targeting a retro-reflective target with a laser.

This target is held in place against whatever is being measured, and as the laser is fired, the light reflects back, with the path of the laser being retraced. A portion of this returned light re-enters the measurement tracker at the precise position it left, and as it re-enters, some of it enters something called a distance meter.

The distance meter is responsible for measuring the distance from the Spherically Mounted Retroreflector (SMR) to the tracker, and one of the two types of distance meters may exist – interferometer and ADM or absolute distance meter.

ADM measures the distance to the target automatically and offers the user the benefit of a much simpler ‘point and shoot’ system. The process works regardless of whether the beam to the target has been broken and involves infrared light from a semiconductor laser reflecting off the SMR and re-entering the tracker. At this point, the onboard circuitry analyses the signal that determines the time of flight.

Once this has been determined, whatever value has been generated is multiplied by the speed of light in air, calculating the distance from the tracker to the SMR.

Conversely, with distance measurement, this can be either absolute or incremental. An incremental measurement is produced when an interferometer and a frequency-stabilised helium-neon laser are used. An incremental movement moves a distance based on your current position. With an absolute measurement, it moves to a coordinate based on your zero point.

Distance measurement was once considered the go-to standard, though ADM is rapidly catching up.

Here at ETG, we can manufacture laser tracking machines that perform both functions. We welcome a discussion to learn more about your requirements.