The EOL Testing Process Explained

The EOL testing process is a critical final step in the manufacturing journey, ensuring that each product meets stringent quality standards before it reaches the consumer. This systematic approach identifies any defects, validates functionality, and guarantees that the product performs as intended. Below are the key steps involved in the EOL testing process:

Product Presentation and Visual Inspection: Finished products are positioned in the bespoke EOL tester, where a thorough visual inspection is conducted to identify any apparent defects or inconsistencies before more detailed testing begins.

Functional Testing and Real-Time Monitoring: The testing equipment is calibrated for specific product requirements. It then executes various tests—such as electrical performance checks and operational efficiency evaluations—while control systems monitor performance metrics in real-time, allowing for immediate adjustments.

Results Analysis and Certification: Test results are compared against predefined quality criteria to determine whether the product passes or fails. Products that meet the standards are certified for quality assurance, while those that do not are flagged for rework or further inspection before they can be shipped.

Real-World Applications of Bespoke EOL Testing

Bespoke EOL testing is vital across various industries, ensuring products undergo thorough evaluation before reaching consumers while adhering to stringent regulatory standards. Key applications include:

Automotive Sector: Testing essential systems like brakes, lighting, and advanced driver assistance systems (ADAS) to guarantee safety and compliance with industry regulations.

Medical Devices: Validating the performance and safety of diagnostic equipment, surgical instruments, and other medical devices to ensure patient safety and effectiveness.

Consumer Electronics: Assessing battery life, display quality, and overall functionality of devices such as smartphones, laptops, and household appliances, which are critical for customer satisfaction and brand reputation.

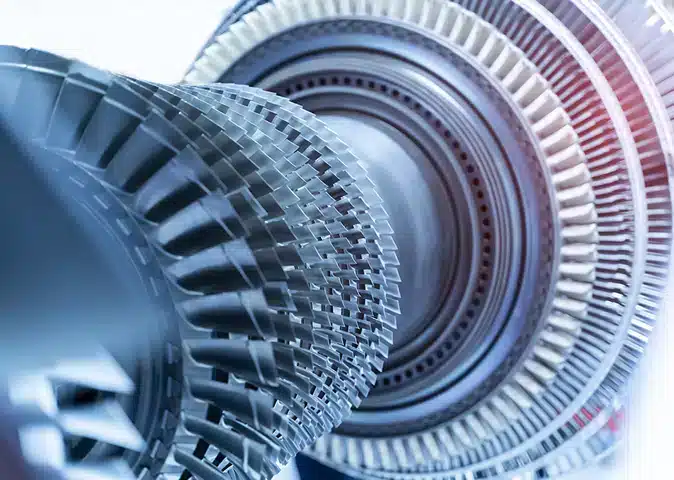

Aerospace: Evaluating aircraft components to ensure durability and reliability in extreme conditions, where performance can significantly impact safety.

Pharmaceutical Packaging: Ensuring the integrity and quality of packaging for sensitive medical products to prevent contamination, thereby maintaining the efficacy of the drugs within.

These applications highlight the extensive role of bespoke EOL testing in industries where safety, performance, and quality are paramount, ultimately protecting consumers and enhancing brand trust.

Future Trends in EOL Testing

The future of EOL testing is shaped by several key trends. Smart testing systems using artificial intelligence and machine learning are becoming more common, improving accuracy and predicting failures before they happen. This proactive approach helps reduce downtime and increase product reliability.

Automation is also on the rise, streamlining processes and speeding up testing without sacrificing precision. Industries like automotive and electronics are leading the way in adopting automated EOL systems.

Additionally, there’s a growing focus on sustainability, with more energy-efficient testing solutions and eco-friendly equipment being developed to align with global environmental goals. Finally, modular and scalable test systems are gaining traction, offering flexibility and adaptability as products and market demands evolve.

Why Partner with Expert Technologies Group?

At Expert Technologies Group, we stand out as a trusted partner for EOL testing solutions, offering unmatched expertise and tailored systems designed to meet your unique manufacturing needs. With decades of experience, we have developed advanced testing equipment that guarantees accuracy, efficiency, and reliability across a wide range of industries.

What sets us apart is our commitment to customised EOL testers. We work closely with our clients to understand their specific requirements, ensuring that every solution is optimised for their production line. This bespoke approach allows us to address even the most complex testing challenges, delivering systems that not only meet but exceed industry standards.

Our cutting-edge control systems ensure precision in every test, helping you maintain high-quality production outputs and reduce downtime. We also integrate sustainable technologies into our processes, offering environmentally conscious testing solutions that are future-proof and energy-efficient.

By choosing us, you’re not just getting a supplier—you’re gaining a partner committed to your success. Our global presence, innovative solutions, and customer-focused approach make us the ideal choice for EOL testing and beyond.